In today's world, industrial development has entered a complex and diverse new era. The widespread use of high-tech such as the Internet of Things, artificial intelligence, and cloud computing has raised higher and more precise technical requirements for industrial robots. For many challenging and demanding tasks, the introduction and collaboration of robots offer new perspectives and solutions to these scenarios. They can not only replace human labor in extreme environments but also perform delicate operations with greater precision that surpass human capabilities. With the development and improvement of collaborative robots (cobots) technology, the application fields and product matrix of robots are constantly expanding, and the range of product models is also becoming more diverse. Cobots have become powerful drivers for industrial development in complex and diverse environments.

Cobots for Diverse Applications

1.Heavy-Load, High Flexible Application

The original intention of cobots design is to achieve characteristics such as safety, lightweight, and high flexibility. Currently, the market is mainly dominated by 3kg-6kg lightweight cobots. However, in recent years, with the increasing demand for heavy-load products in industries such as mechanical processing, automotive parts, home appliances, food and beverages, medical supplies, etc., they have been widely used in high rigidity and heavy-load scenarios, including welding, handling, packaging, palletizing, etc.

Palletizing is a key application of cobots. In recent years, palletizing application has evolved from large quantities and fixed sizes of goods to on-demand production with various types and smaller batches. This change has increased the requirements for cobots in terms of flexibility and load capacity. Cobots need to be able to adapt to different sizes, weights, and shapes of goods, as well as adjust work tasks and positions to meet production needs quickly.

(Picture Source: ELITE ROBOTS)

Traditional industrial robots cannot meet the flexible and agile production requirements, while lightweight cobots cannot meet the requirements of heavy load and high rigidity operations in production. In this case, heavy-load cobots can satisfy the requirements of heavy load and long radius, while also possessing higher flexibility, precision, and safety. They have filled the current market gap to some extent. Currently, many cobots manufacturers such as ELITE ROBOTS, UR (Universal Robots), JAKA, AUBO have conducted research and development on products with heavy load capacity and long radius. Among them, ELITE ROBOTS developed the CS620 cobot with a radius of 1800mm and a load capacity of 20kg, the CS625 cobot with a radius of 1500mm and a load capacity of 25kg, as well as the CS520H cobot with a radius of 2,000mm and a load capacity of 20kg in 2023. These robots not only achieve a long radius but also meet practical load requirements, making them suitable for scenarios such as handling and palletizing, greatly expanding their application space in the market.

2.“Technical Tasks” Application

There are many pain points in fine work such as screw locking, gluing, polishing, deburring, welding, cutting, etc., and there is a high demand for "automation replacing human labor". For example, in screw locking industry, manual work has high intensity and the assembly quality is not uniform enough. It is difficult to improve the yield of finished products; in gluing industry, traditional industrial robots need to be separated from workers by safety barriers due to safety limitations. The utilization rate of the production line is limited and it is difficult to control the accuracy and quality of manual gluing.

Can cobots flexibly meet the above-mentioned "technical tasks"? Domestic robot manufacturers have given us the answer.

(Picture Source: ELITE ROBOTS)

ELITE ROBOTS has developed the CSR rotary series cobot specifically for fine application scenarios. Compared to other cobot products, CSR simplifies the end joint and reduces the distance between end tool and end axis, making it more flexible during operation and meeting the process requirements of screw locking in narrow spaces with difficult angles and various complex workpieces. When combined with force control instructions and force control process packages, it can achieve precise operations such as complex surface polishing.

Cobots have great potential in addressing the pain points of fine work and meeting the demand for "technical tasks". Domestic robot manufacturers have successfully offered solutions by conducting research and developing innovative products.

(Picture Source: ELITE ROBOTS)

3.Operation in Special Environment

Moisture and dust are common challenges in many industrial operations. Apart from basic indicators like load, radius, and accuracy, the protection level is crucial for robots. IP68 serves as the industry's highest standard for waterproofing and dustproofing, acting as a benchmark to test the protection level of cobots. ELITE, a Chinese manufacturer of cobots, recently announced that its CS series and sub-series all come equipped with IP68 as a standard configuration. This achievement signifies their excellent performance in meeting this high-end indicator of protection level.

(Picture Source: ELITE ROBOTS)

In high-risk working environments such as oil, chemical, and coal mining industries, serious accidents such as explosions and fires may occur during transportation and storage. This poses higher requirements for the protective functions of cobots. Currently, replacing manual labor with robots in daily operations has become a trend. In order to meet the demands of high protection standards for work environments, ELITE has also developed the CS explosion-proof series cobots with high safety explosion-proof technology specifically designed for hazardous and flammable environments.

Expand Product Matrix to Meet the Needs of Segments

Broaden Product Matrix and Bring Forth New Ideas from General Industry to Market Segment

Cobots are mainly used in downstream industries with flexible and non-standard scenarios. There are various types of downstream industries for cobots, which have typical non-standard attributes. For example, in industries such as aviation, automotive, electronics, etc., the tasks that require precise control and complex operations are constantly increasing. The performance, functionality, and specifications of cobots also vary in different industries.

In the current stage of cobots market development, there are many manufacturers producing similar products, and the capital market is beginning to slow down. Cobots manufacturers are venturing beyond traditional industrial applications and expanding their product range based on customer needs and industry challenges in order to improve their competitiveness. The cobots market is gradually transitioning from a general focus to more specialized sectors.

(Picture Source: ELITE ROBOTS)

In 2023, the cobots market is experiencing rapid growth, with major manufacturers competing to launch new products. By making breakthroughs and innovations in integrated technology research and development, manufacturers are constantly expanding new application scenarios for their respective industries, bringing continuous vitality into the entire cobots market. ELITE has consistently embraced the concept of innovation by deviating from traditional scenarios and conducting product research and development that addresses real industry pain points. In 2023 alone, ELITE has introduced 29 new models, adapting to market developments and meeting customer needs.

Explore Diverse Scenarios and Provide Customized Solutions

In the complex market competition, cobots manufacturers realize that simply providing the robot itself cannot meet customers' needs. Therefore, they continuously innovate by deeply exploring diverse industry scenarios and customizing solutions. The introduction of these customized solutions not only improves the practicality and applicability of robots but also further expands their application scope. Industries such as photovoltaics, lithium batteries, and new energy vehicles have been developing rapidly in the past two years. Chinese cobots manufacturers are tapping into downstream market one after another to seize market share.

(Picture Source: ELITE ROBOTS)

Recently, a leading electronics, automotive, and new energy company signed the largest single order in the global cobots market with ELITE. The order includes over 2000 domestic 6-axis cobots.

According to principal of ELITE, "Large order is good news for the entire industry. This proves that the track of cobots is becoming wider and ecological partners will have more confidence in cobots. ELITE will actively respond to market changes, continue to explore incremental opportunities, adhere to product improvement. While continuing to deepen roots in the domestic market, ELITE will continue to expand into overseas markets and showcase the power of ‘Intelligent Manufacturing in China’ to the world.”

Cobots are safe, flexible, easy to use, and have a high return on investment. They are particularly suitable for semi-automatic lines and pilot lines in the later stages of lithium battery production. There are many opportunities for application in processes such as testing, gluing, labeling, welding, loading and unloading materials, and locking.

It is understood that ELITE has achieved practical applications in various industries such as new energy vehicles, lithium batteries, and automotive electronics during processes such as core manufacturing, module assembly, PACK line, etc. These applications include online cleaning of lower casings, installation and fixation of modules, airtight testing of water cooling circuits, assembly and tightening of upper cover plates, ATS testing, BUD&Bus assembly/tightening to address the pain points and meet needs of customers.

Overall, cobot manufacturers continuously innovate to meet customer demands, enhance product competitiveness, and drive the development of the entire industry.

Cobot Market Analysis

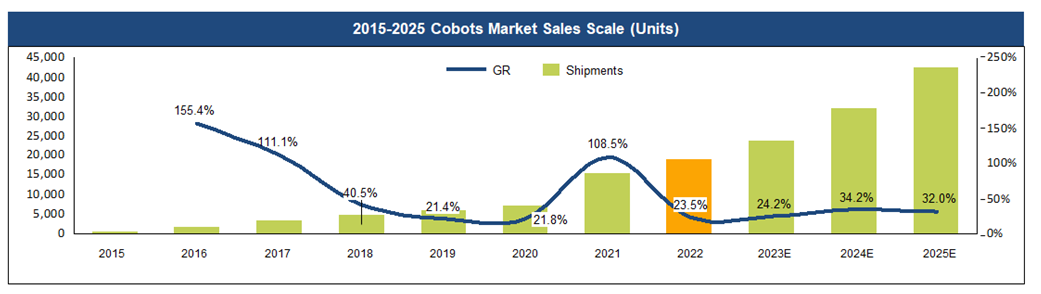

With the increasing demand for flexible automation upgrades in traditional manufacturing industries represented by 3C electronics and automobiles, cobots have solved many challenges of flexible automation transformation for manufacturing enterprises with their advantages of flexible deployment, efficiency improvement and cost reduction, leading to a significant increase in the demand for cobots and a good market growth.

2015-2025 Cobots Market Sales Scale

(Data Source: MIR DATABANK)

Potential Market Opportunities for Cobots in the Long Term

Cobots are highly compatible with the transformation needs of manufacturing enterprises for intelligent manufacturing, human-machine collaboration, and flexible manufacturing. They can not only be applied in the industrial sector but also explore new scenarios in non-industrial sector such as catering, healthcare, agriculture, and rail transit. The demand for non-industrial scenarios is yet to be further developed, showing a wide range of application possibilities.

Ending

As the cobots market thrives, both new cobot manufacturers and traditional industrial robot manufacturers are entering the market to seize market share. In response to intense competition, robot manufacturers are actively addressing challenges by exploring various industry scenarios and offering customized solutions. Simultaneously, domestic cobots are consistently making self-improvements and advancements, adapting to diverse industry requirements through optimization of performance and functionality.

In the future, we can expect robots to continue emerging and being applied in-depth across various industry sectors. With advancing technology and expanding applications, robots will bring revolutionary changes and growth opportunities to multiple industries.

(Picture Source: ELITE ROBOTS)